With some incredible minds at the helm of research and development, cheaper and brighter LEDs are closer to us every day! The technology keeps getting better and new applications for LEDs are discovered regularly.

As the technology continues to improve and becomes more affordable, the few remaining holdouts find their case against the mighty LED steadily weakening. Two recent research breakthroughs hit holdouts right where it hurts:

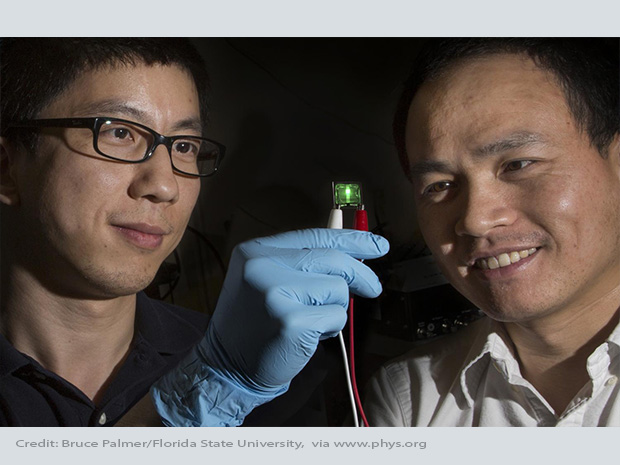

Firstly, a researcher at Florida State University (FSU) has discovered a new, highly efficient method of LED production that could see the cost of manufacturing LED bulbs drop dramatically.

And secondly, researchers at Princeton have found a way, using nanotechnology, to vastly improve the efficiency of light output, which, in turn, improves the image clarity of LED displays by approximately 400 percent. It is breakthroughs like these that help solidify LEDs’ position as the most efficient and cost-effective lighting option on the market today — with an exceptionally bright future ahead. Read on to learn more about these researchers and their fascinating discoveries.

Cheaper and Brighter LEDs are Here to Stay.

Pero-PEO method reduces manufacturing costs without sacrificing brightness

Zhibin Yu, Assistant Professor of Industrial and Manufacturing Engineering at FSU is optimistic that his new, highly efficient method of LED production will help encourage more people to embrace LEDs. “It can potentially revolutionize lighting technology,” Yu explains.

“In general, the cost of LED lighting has been a big concern thus far. Energy savings have not balanced out high costs. This could change that.”

Yu’s discovery, which was published in the Advanced Material journal in September of 2015, focuses on simplifying the process by which organometal halide perovskite (Pero) materials are used to make LEDs. The big change comes from simplifying the current, multilayer architecture into a single-layer using a composite thin film of Pero and poly(ethylene oxide) (PEO).

This change is exciting not only because it simplifies and reduces the cost of manufacturing, but also because Yu and his team have successfully streamlined the structure while maintaining a high level of luminance typically found in multilayer devices.

In addition, the team’s Pero-PEO composite thin films can glow red, green, blue, or all three colours together to produce white light and can be produced at room temperature instead of traditional high temperature processing, which, as Yu explains, “[makes] the process inexpensive and highly manufacturable.”

57 percent increase in light output for organic LEDs (OLEDs)

A common complaint that has plagued LEDs has been the perceived lack of brightness or reduced light quality due, in large part, to the fact that only a fraction of the light an LED generates actually makes it beyond the lens. This is because light is not channeled from where it is generated at the semiconductor junction, but rather focused by the crude lens of the epoxy resin medium in which the semiconductor is contained.

If trying to make sense of semiconductor junctions and epoxy resins makes your head spin, professor Stephen Chou, Princeton’s Joseph C. Elgin Professor of Engineering, has an easier explanation: “It is exactly the same reason that lighting installed inside a swimming pool seems dim from outside – because the water traps the light. The solid structure of a LED traps far more light than the pool’s water.”

To combat this effect, Chou and his team at Princeton University have devised a new method that improves the way in which light is emitted from LEDs. The team designed a nanoscale structure, which they call a plasmonic cavity with subwavelength hole-array (PlaCSH) to manipulate light in a novel way.

Consisting of a layer of light-emitting material that is approximately 100 nanometers thick housed inside a cavity made with one side of thin metal film and the opposite side coated with an ultra-thin metal mesh, the PlaCSH device effectively guides the light out of the emissive layer with almost no absorption or scattering. The result is significantly improved light output and image clarity.

What might be most surprising about this breakthrough is that it is actually quite cost-effective. Chou’s “nanoimprint” technology makes nanostructures in much the same way a printing press makes newspapers. Currently Chou and his team are looking at expanding the use of PLaCSH in red and blue organic LEDs, and fine tuning the original green LEDs. To help facilitate further research, the US Department of Energy recently awarded Chou a grant so that he may continue research and development of the PlaCSH.

Researchers like Yu and Chou (and their respective teams) are champions for positive change – they seek opportunities to make a good thing even better and use their expertise to help ensure innovative technology is available to all. As for the holdouts — Sometimes it is easy to criticize the skeptical and slow to change, but they do challenge the status quo in their own way. Remember, when it comes to change: No contribution is too small and cheaper and brighter LEDs are possible, and much closer with these two discoveries!

About The Author

- Serial Entrepreneur, Technologist and Inventor my objective is to develop useful products that have a net positive effect in the lives of those that use them and the environment that we live in. CEO of Mission LED Lighting Company Ltd.

- 2017.12.27UncategorizedSaving the World and Saving Money: Green Home Improvements Every Homeowner Should Make

- 2017.01.17Be green & save5 Simple Green New Year Resolutions For 2017

- 2016.11.09LED factsReplacing a 400 HID Lamp for an LED

- 2016.09.26Be green & saveVintage LED Bulbs Make What’s Old New Again

Leave a Reply